- within Media, Telecoms, IT and Entertainment topic(s)

The application relates to determining the optimal location of additional welded points to be added to the automotive body. The Examination Division considered that it was merely automating the non-technical method steps. The Board disagreed and considered that it was technical as designing an automotive body in which the stiffness of the automotive body during driving is improved is technical, and since the claim indicates that "to be added to the automotive body", it is implicit that it is a technical use.

Here are the practical takeaways from the decision: T 0799/24 (Optimisation of vehicle body joint position/JFE STEEL CORPORATION) of August 21, 2025 of the Technical Board of Appeal 3.5.07.

Key takeaways

Additional welded point(s) is/are "to be added" to the automotive body to improve its stiffness during driving at least implicitly specifies a further technical use.

Designing an automotive body in which the stiffness of the automotive body during driving is improved is technical

The analysis results is used in the automotive body designing. The possible use by the user of the displayed analysis results might be a cognitive exercise such as selecting the automotive body corresponding to the lowest displacement amount, but the board considers that the step of selecting the additional welded points contributes to the technical character of the invention.

The additional welded points of which the locations are determined or selected are "to be added to the automotive body" ("to improve the stiffness of the automotive body during driving") at least implicitly specifies a further technical use

Even if the automotive body was a "prototype" and the additional welded points were added to this "prototype", this "prototype" would still be a physical object having at least some of the features of an automotive body.

The decision of the Enlarged Board of Appeal G 1/19, requires a simulation to be "accurate enough" or a simulation that reflects "reality" "accurately enough". In the present case, the automotive model constituted by the automotive body frame model and the chassis model together with the welded points at the joining portion(s) is considered to reflect an automotive body (as "reality") "accurately enough".

The invention

The Board defined the invention as follows:

1. The aim of the invention is to provide an analysis apparatus for determining an optimal location of an additional welded point to be added to a portion to join a part to an assembly of parts in consideration of the load acting on the automotive body and of the inertia force acting on a fitting or lid component of the automobile during driving (paragraph [0014] of the description as filed).

2. The board notes that the results of the operation of the subject-matter of claim 1 are:

R1) an automobile model (61) generated by joining an automotive body frame model (31) to a chassis model (51);

R2) an optimisation analysis model;

R3) a load or displacement generated, during driving and steering of the automobile model, at a joining portion to the chassis model on the automotive body frame model, and of which magnitude and direction are different at each joining portion;

R4) a location of an additional welded point or an additional welded location, satisfying optimisation analysis conditions, to be added to the automotive body;

R5) analysis results for automotive body designing.

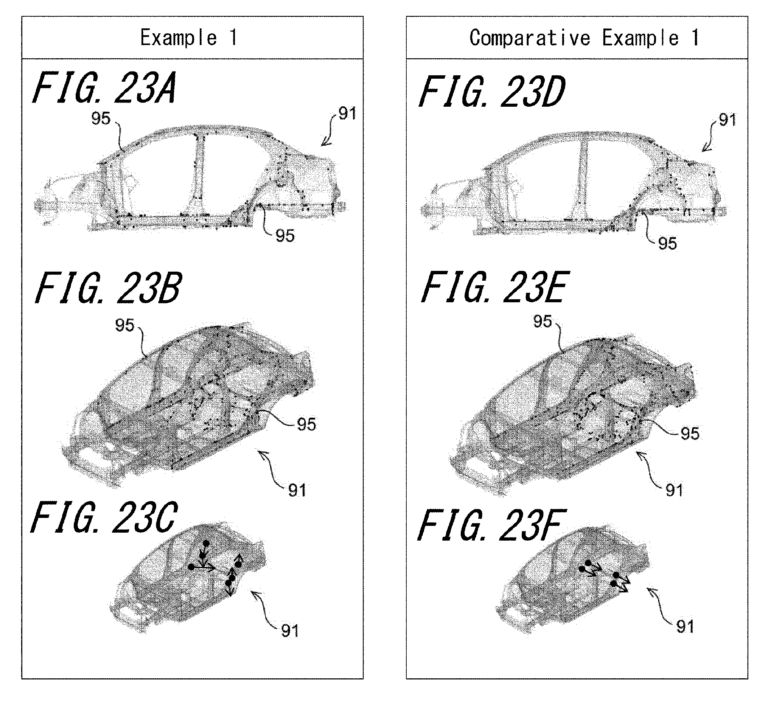

Fig.23 of EP 3 525 115 A1

-

Claim 1

Is it patentable?

The Examining Division considered that the claim lacked inventive step, starting from a general-purpose computer, as it relates to automating the non-technical method. The Board disagreed:

4.2 In the board's view, the problem of using this general approach is that the "resulting method" does at least reflect some intrinsic technical features: for example "one of a load or displacement generated at a joining portion to the chassis model (51) on the automotive body frame model (31) during driving", the "driving conditions" such as "driving and steering of" an automobile model, "an additional welded point or an additional welded location" (the influence of its physical weight for example), calculated "absorbed energy" and "stiffness" (by the "optimisation analysis model").

4.3 The board is of the opinion that the differences between the subject-matter of claim 1 and a general-purpose computer are that the analysis apparatus of claim 1 uses an automotive body frame model as defined by feature (b) to perform an optimisation analysis of spot welding or continuous welding as defined by feature (c). The analysis apparatus comprises the automobile model generation unit of feature (d), the driving analysis unit of feature (e) having driving conditions set as defined in feature (f). It further comprises an optimisation analysis model generation unit as defined by features (g) and (k) using optimisation analysis conditions set by the optimisation analysis condition setting unit defined by features (h), (l), (l1) and (l2). An optimisation analysis unit of feature (i) performs an optimisation analysis as defined by features (i1) and (i2).

4.4 The additional welded point(s) is/are "to be added" to the automotive body to improve its stiffness during driving. In the board's view, this formulation at least implicitly specifies a further technical use (see decision G 1/19, points 124 and 137).

4.5 Therefore, the subject-matter of claim 1 of the main request involves an inventive step over a general-purpose computer (Article 56 EPC).

Then the Board discussed the distinguishing features over document D1:

23. Therefore the distinguishing features of claim 1 of the main request having regard to the disclosure of document D1 are:

DF1|the automobile model (61) is generated by joining the automotive body frame model (31) to a chassis model (51); |

DF2|an optimisation analysis unit (23) that performs an optimisation analysis on the welding candidates by applying at least one of the load, of which magnitude and direction are different at each joining portion, generated at the joining portion acquired by the driving analysis unit (17), to select an additional welded point or an additional welded location that satisfies the optimisation analysis conditions from the welding candidates and thereby determine a location of the additional welded point or the additional welded location to be added to the automotive body (to improve the stiffness of the automotive body during driving);|

DF3|the driving conditions set in the driving analysis unit (17) include "driving and steering" of the automobile model (61); |

DF4|the optimization analysis model generation unit (19) sets the welding candidates at a predetermined interval between welded points or welded locations preset on each assembly of parts of the automotive body frame model (31); |

DF5|the objective condition includes minimising strain energy and maximising absorbed energy to minimise generated stress. |

The Board accepted the technical effect formulated by the applicant:

25. The appellant considered the objective technical problem as being how "to design an automotive body in which the stiffness of the automotive body during driving is improved". The board accepts this as the objective technical problem.

The Board considered that the features DF2 and DF5 are not disclosed or obvious. However, the Board discussed the

34. In the statement of grounds of appeal, the appellant argued that it was clear from the claim wording that the displaying of the analysis results was not aimed at the user for subjective evaluation or non-technical decision-making but intended for improving the stiffness of an automotive body during driving. Improving the stiffness of an automotive body (the automotive body was not a model, but a real object from the physical world) during driving was clearly an objective evaluation of technical decision-making.

The display of the analysis results concerned an objective evaluation of the stiffness of the automotive body and the location of additional welded points/locations using objective criteria.

34.1 In the board's view, since the use of the analysis results is defined in the claim as being "for automotive body designing", leaving it open which further steps, technical or not, are performed with the analysis results, a potential further selection of a particular automotive body might also be based on the visual characteristics or appearance of the automotive body. However, the board is of the opinion that the selection of the automotive body is, in addition, also restricted to the selected additional welded points to be added to the automotive body.

35. According to the appellant, the claim is limited to the intention of realisation, i.e. manufacturing, of a corresponding automotive body, in particular, determining a location of additional welded points or additional welded locations to be added to the automotive body to improve the stiffness of the automotive body during driving. The automotive body is not a model, but a real body from the physical world. The intended technical effect achieved by the claimed features is to improve the stiffness of the automobile during driving with high accuracy by adding additional welded points or additional welded locations at an optimal location on the automotive body.

36. The board notes that the optimisation analysis on the welding candidates applies at least one of the load, of which magnitude and direction are different at each joining portion. An additional welded point or an additional welded location that satisfies the optimization analysis conditions, including maximising absorbed energy, is selected.

37. The board further notes that the additional welded points of which the locations are determined or selected (via the optimisation analysis unit of distinguishing feature DF2 having optimisation analysis conditions including the objective condition of maximising absorbed energy of distinguishing feature DF5, see also output R4) under point 2. above) are "to be added to the automotive body" ("to improve the stiffness of the automotive body during driving"). In the board's view this wording at least implicitly specifies a further technical use (see decision G 1/19, points 124 and 137).

38. Moreover, the analysis apparatus aims at optimizing a joint location of an automotive body in order to improve the performance, such as the stiffness of an automotive body during driving. In essence, an optimisation analysis of the welding candidates is performed by simulating driving via the automobile model.

39. According to the appellant, which referred to points 124, 137 and 138 of G 1/19, a further technical use of the outcomes of the optimisation analysis unit was explicitly defined in claim 1, namely adding the additional welded point or the additional welded location to the automotive body to improve the stiffness of the automotive body during driving. It was clear to the skilled person from the wording of claim 1 that the additional welded point or location determined by the optimisation analysis was intended for the actual welding step of the automotive body. The appellant also referred to paragraph [0090] of the description referring to specific welding means, such as "spot welding", "laser welding" and "arc welding". Therefore, the outcome clearly related to the real world and had an impact on the physical reality.

40. According to the appellant, by virtue of the explicitly defined automotive body representing a real-world, i.e. physical, component to be obtained via the optimisation, the claims are specifically directed to the technical purpose of obtaining an optimised automotive body, and have the potential technical effect of obtaining the improved automotive body from the analysis results.

40.1 The appellant further argued, referring to points 89 to 96 of decision G 1/19, that the intended technical use was that of obtaining a real automotive body having improved performance such as stiffness during driving. This had nothing to do with speculations, studies or economic evaluations on how a simulated component could result, as a consequence of the claim expressly referring to the optimisation of a joint location of the automotive body, i.e. of an automotive physical component.

41. The appellant argued that the additional welded point/location was to be added to the automotive body, and not to a model, the automotive body being a real object in the physical world.

42. The appellant argued that decision G 1/19 did not require including an explicit step of actually welding a real-life automobile frame at the optimal welding locations, in order to limit the claim to a further technical use. As shown in point 88 of decision G 1/19, there was no need for a direct link with (external) physical reality in every case and hence it was not necessary to specify a step of adding the additional welded point or the additional welded location to the automotive body.

43. The board considers that it is implicit from claim 1 that the additional welded points of which the locations are determined will be added to the automotive body (see point 37. above). The technical effect is therefore considered to be achieved by the distinguishing features over the whole scope claimed.

44. The analysis results (see R5 in point 2 above) used in the automotive body designing are, for example, "automotive body displacement amount". They are illustrated, in the application as originally filed, in Figures 19A to 19D, in which the automotive body is shown from the front left side, and 20A to 20D in which the automotive body is shown from the rear left side (paragraph [0110] of the application as originally filed). The possible use by the user of the displayed analysis results might be a cognitive exercise such as selecting the automotive body corresponding to the lowest displacement amount (see Figures 19A to 19D and 20A to 20D of the application as filed and decision G 1/19, point 138), but the board considers that the step of selecting the additional welded points contributes to the technical character of the invention.

It might be that the location(s) of the additional welded point or the additional welded location(s) to be added to the automotive body (to improve the stiffness of the automotive body during driving) determined by the optimisation analysis unit of the analysis apparatus of claim 1 is or are displayed as part of the analysis results, but the claim leaves it open.

45. The board considers that, even if the automotive body was a "prototype" and the additional welded points were added to this "prototype", this "prototype" would still be a physical object having at least some of the features of an automotive body.

46. The board notes that the decision of the Enlarged Board of Appeal G 1/19, point 111 requires a simulation to be "accurate enough" or a simulation that reflects "reality" "accurately enough". In the present case, the automotive model constituted by the automotive body frame model and the chassis model together with the welded points at the joining portion(s) is considered to reflect an automotive body (as "reality") "accurately enough".

The content of this article is intended to provide a general guide to the subject matter. Specialist advice should be sought about your specific circumstances.