- within Antitrust/Competition Law and Compliance topic(s)

Executive Summary

As global supply chains face disruptions, escalating geopolitical pressures, and tariffs, manufacturing leaders must blend automation and skilled labor to shield margins and ensure continuity. This creates a need to address the balance between labor and automation in production processes in order to increase efficiencies. As a result, the demand for skilled labor to support automated systems will continue to increase and bring with it critical implications for productivity, cost, and employment.

This paper delves into the dynamics of labor versus automation, exploring the role of skilled labor in an increasingly automated landscape. It provides insights into various automation opportunities and underscores the necessity of investing in workforce development to support these technological shifts. By pairing automation with targeted workforce development, companies can directly mitigate tariff risk, lower landed costs, and maintain a competitive advantage.

In addition, recent legislative changes have created opportunities to invest in automation. The recently passed One Big Beautiful Bill Act (OBBBA) reinstates and makes permanent the 100% bonus depreciation provision that had been phasing out under the 2017 Tax Cuts and Jobs Act (TCJA). Businesses can now fully expense the cost of qualified capital investments in the year the asset is placed in service. This applies to property placed in service after Dec. 31, 2025, with no scheduled phase-out.

Eligible Property Includes:

- Machinery and equipment

- Vehicles and aircraft used in business

- Furniture and fixtures

- Certain improvements to nonresidential real property

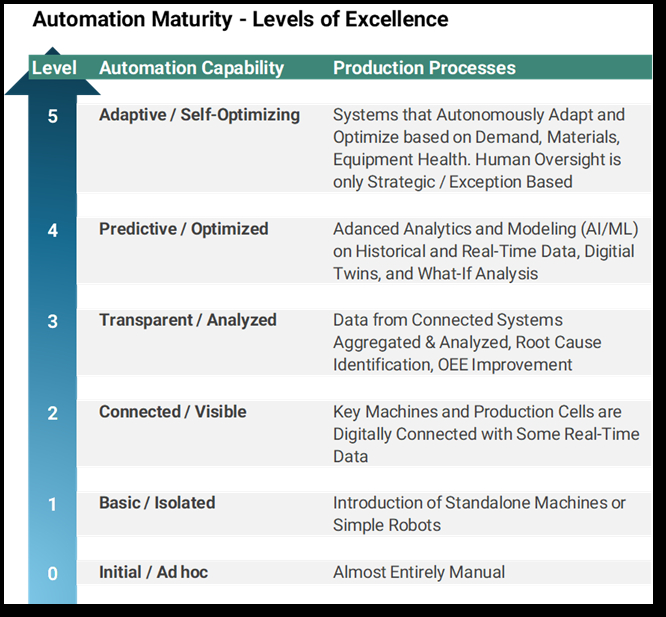

The Rise of Automation

A company's automation maturity level can be classified based on a continuum from Initial / Ad hoc to Adaptive / Self-Optimizing. The maturity level required depends on each company's needs and goals. Each level of development depends on increasingly skilled labor to enable growth to higher levels of manufacturing automation proficiency.

Another important area to consider is the automation maturity of your component suppliers' manufacturing processes. Bringing focus to this can help your partners to lower the costs of raw materials for final assembly and integrate higher efficiency throughout your extended supply chain.

Thoroughly evaluating the current state of your company's manufacturing automation, processes, equipment, and systems can uncover significant opportunities to unlock increased sales and profitability.

Key Enablers Driving Automation

Several technological advances have coalesced over time to allow significant progress in manufacturing automation.

- Robotics:Collaborative robots (cobots) that work alongside human workers for tasks like assembly and packing. Industrial robots designed for high-speed and precision tasks that can operate in various environments.

- Artificial Intelligence (AI):Machine learning algorithms that analyze data from manufacturing processes to improve efficiencies and predict machine failures. AI-driven quality control systems that identify defects faster and more accurately than human inspectors.

- Industrial Internet of Things (IIoT): Smart sensors and devices that collect real-time data on production metrics, equipment performance, and environmental conditions. Enhanced machine-to-machine communication leading to better synchronization of production processes.

- Additive Manufacturing:3D printing technologies allow for rapid prototyping and the creation of complex parts with minimal waste, transforming traditional manufacturing workflows.

- Supply Chain Automation:Software solutions for inventory management, order processing, and logistics that allow real-time tracking and optimization based on demand forecasts.

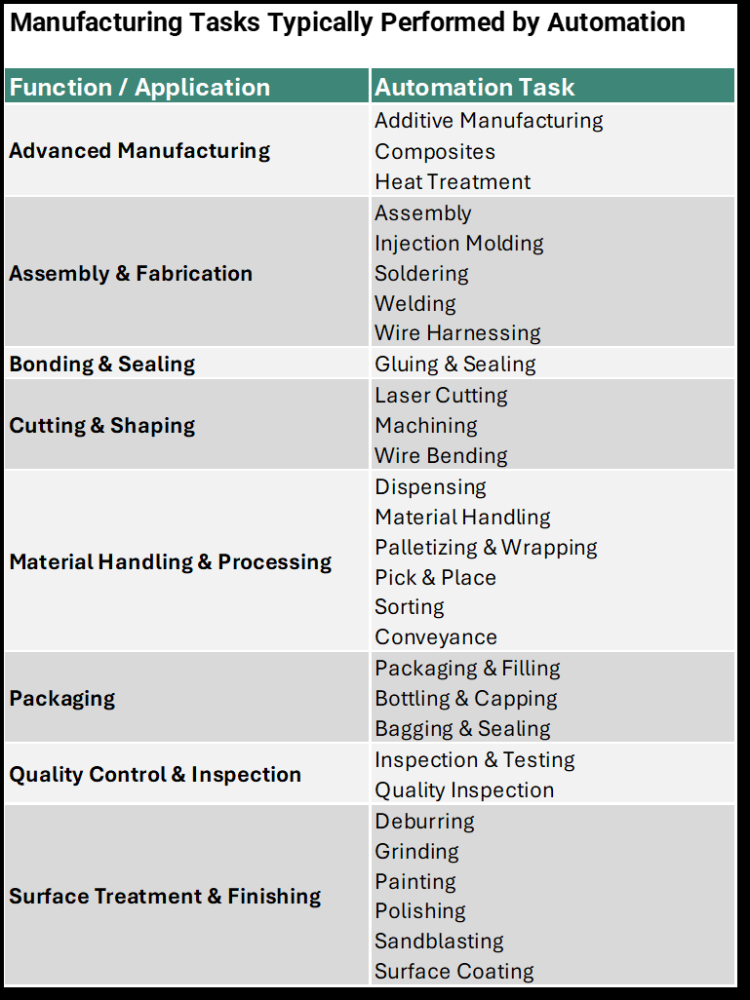

These advances support the progress of automation in many areas throughout manufacturing processes. In addition to robotics applied to tasks, such as assembly or welding, there are aspects of material handling and packaging that can also contribute to significant efficiency and production capacity gains.

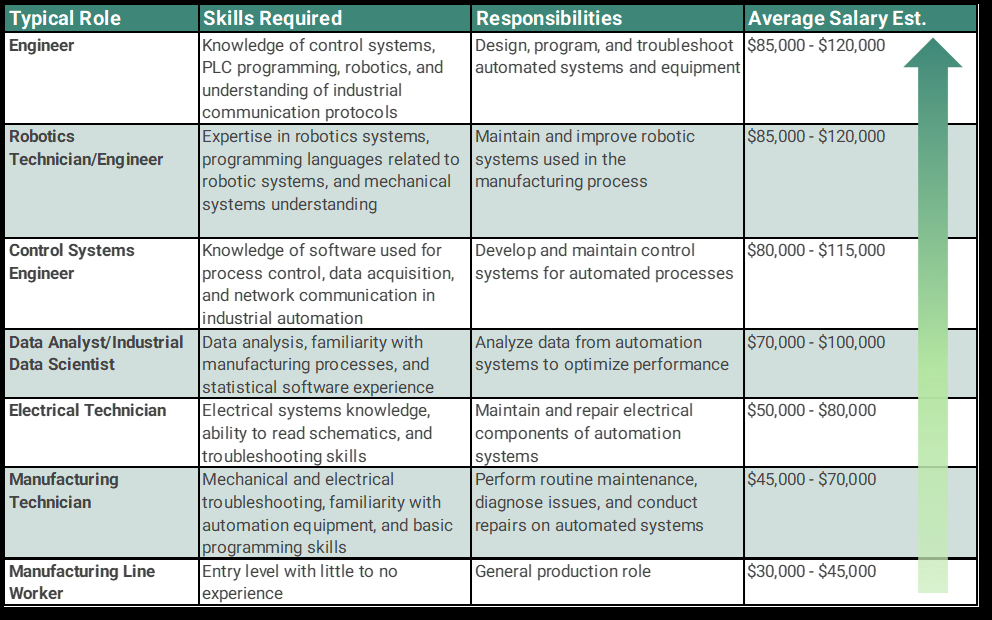

Skilled Labor Roles That Support Automated Manufacturing

The skilled labor required to maintain automation in manufacturing encompasses a variety of specialized roles with significantly higher average salaries compared to traditional manufacturing line workers. As automation continues to evolve, the demand for skilled labor in these areas is expected to grow, reflected in higher wages and more specialized training requirements.

Source: US Bureau of Labor Statistics

Evaluating Automation Needs and Economic Payback

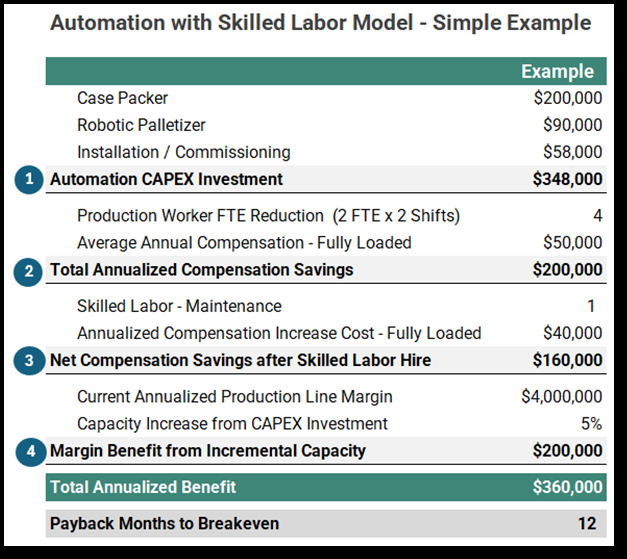

Significant levels of automation may not be required in all industries. Determining the right level of automation can help companies to maximize efficiency, while optimizing the economic payback from capital investment.

In doing this, it is important to understand the capital expenditure (CAPEX) cost of automation equipment, including installation, calibration, and integration with control systems. This cost can be balanced against the reduction of unskilled production labor, combined with investment in skilled labor required to run new automated equipment and systems. Additional forecasted capacity and resulting margin from incremental production attributed to the new equipment should be considered. This will allow the company to understand the total annualized benefit from the investment along with the projected payback period.

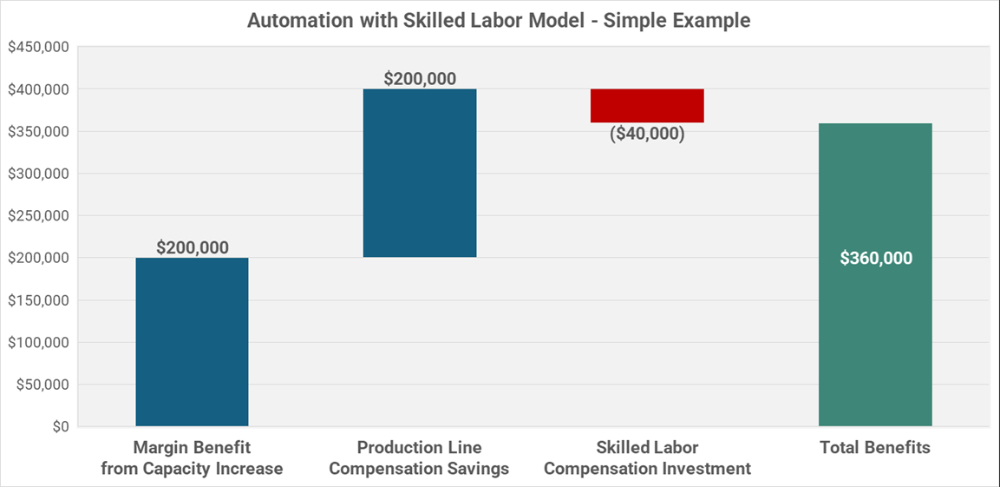

In the simplified example below, we are modeling a production line that makes $10 million of revenue at 40% margin.

- The company has identified a total CAPEX investment of $348,000 that includes a Case Packer ($200,000), Robotic Palletizer ($90,000) and Installation / Commissioning costs ($58,000).

- There are four people on the line that the company has identified for reduction, to be replaced by upscaling an existing resource to a higher skill level, focused on monitoring and maintenance of the new equipment (an additional $40,000 of total compensation).

- The total annualized benefit to the company from this simplified example is then $360,000.

Evaluating each step of a production line for automation

opportunities, while quantifying the cost/benefit of the cumulative

improvements in a modeling tool, allows your company to understand

the optimal combination of investments. This analysis can also

pinpoint key areas where bottlenecks exist and highlight critical

opportunities for improvement.

Customized Automation and Maintenance Implications

Automation solutions are generally not one-size-fits-all; they often need to be tailored to specific operational needs. Skilled professionals play a vital role in configuring these systems to meet the unique demands of their business environment. This involves coding, programming, and customizing modules for enhanced efficiency.

Once tailored to specific operational needs, automation requires regular maintenance and updates to ensure that machines and systems function optimally. Such roles often involve troubleshooting, repairs, software updates, and hardware replacements.

As automation evolves, so too must the skills of the workforce. Companies need to invest in training programs that can upskill existing employees where needed to work alongside automated technologies.

Conclusion

As the pace of technological advancement has accelerated, the dynamic tension between labor and automation has intensified. Automation has transformed numerous industries, leading to increased efficiency, reduced costs, and improved productivity. However, the integration of automated systems presents significant challenges, particularly in the need for a skilled workforce to maintain these technologies.

With the recent implementation of significant tariffs and the trend toward decreased globalization, the opportunity for efficient onshoring has become a problem that manufacturing automation and skilled labor can help solve.

Ankura Performance Improvement Fundamentals

We have a proven track record of executing on strategic plans to achieve sustainable performance improvement and targeted operating results aimed at maximizing earnings before interest, taxes, depreciation, and amortization (EBITDA), cash flow and ultimately shareholder value.

We work side-by-side with management and other stakeholders to guide companies through periods of uncertainty and subsequently accelerate growth and value creation.

Ankura's Performance Improvement professionals leverage the deep expertise across the firm to bring the appropriate specialized resources to deliver solutions to complex problems to create optimal outcomes.

Ankura Supports Manufacturers by Identifying and Executing Productivity and Profit-Driving Opportunities

At Ankura, we help manufacturing organizations unlock performance and profitability through targeted improvements across operations, supply chain, and workforce strategy. Our integrated approach includes:

The content of this article is intended to provide a general guide to the subject matter. Specialist advice should be sought about your specific circumstances.