- in European Union

- in European Union

- within Transport and Consumer Protection topic(s)

- with readers working within the Telecomms industries

What is CCUS?

The International Energy Agency (IEA) defines Carbon Capture, Utilization and Storage (CCUS) as a group of technologies for capturing of CO2 from large and stationary CO2 emitting sources, such as fossil fuel-based power plants and other industries. CCUS also involves the transport of the captured CO2 (typically by pipeline and in certain situations through shipping, rail or trucks also) to sites, either for utilization in different applications or injection into geological formations or depleted oil & gas fields for permanent storage and trapping of the CO2.

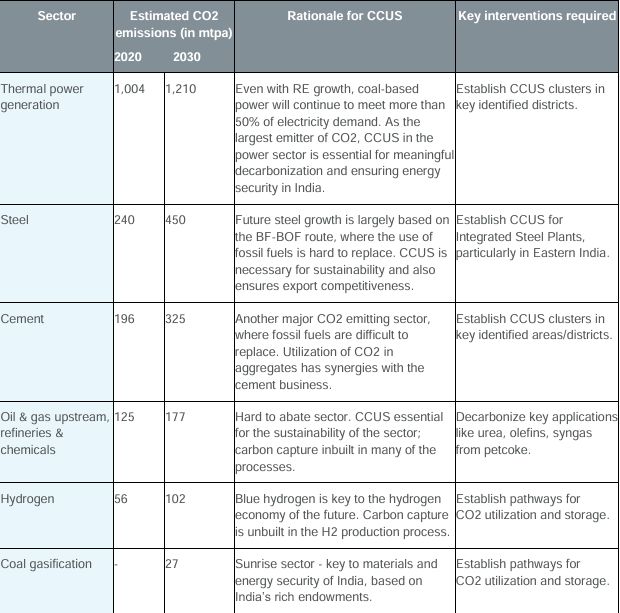

Sectors in India which will require this

Power: Mainly thermal power generators using traditional fossil fuels like lignite, coal, naphtha, etc.

Steel: The future growth of the steel industry in India is largely expected to be based on fossil fuels and the CO2 intensive BF-BOF route, given the scarcity of scrap and natural gas in India. CCUS is necessary for ensuring the sustainability of this critical sector of the Indian economy and also ensuring export competitiveness.

CCUS can also enable the scalable and profitable conversion of waste gases from Blast Furnace, Coke Oven and Basic Oxygen Furnaces of Integrated Steel Plants to blue hydrogen at a cash cost of less than Rs. 100 per kg. Blue hydrogen can be used within the steel plant as a source of clean energy or for producing clean DRI. The blue hydrogen can also be sold to external consumers, thus propelling the clean hydrogen economy in India.

Cement: Cement is another major CO2 emitting sector, where fossil fuels are difficult to replace in the cement making process. The capture, sequestration and conversion of CO2 to aggregates and other chemical products provide synergies for the cement sector.

Oil & gas, refineries and chemicals: This is another hard-to-abate sector, where CCUS is essential for ensuring sustainability. Carbon capture is inbuilt in many of the processes, which makes CCUS costs competitive for this sector.

Hydrogen production: The cost-competitive production of blue hydrogen using India's rich coal endowments is key to enabling the hydrogen economy of the future. Carbon capture is inbuilt in the H2 production process, leading to cost competitive CCUS.

Coal gasification: Coal gasification is a sunrise sector and key to ensuring the materials and energy security of India, based on India's rich endowments of coal. CCUS is critical to enabling the coal gasification economy in India and the production of clean products.

CCUS in India

Presently carbon capture in India is confined to certain industries/applications where the carbon capture is part of the process, viz., the manufacture of urea. India's urea production is about 24 mtpa, where capture CO2 is utilized in the ammonia to urea conversion process. CO2 is also captured as part of the gas conditioning process in the gasifiers of Reliance Industries Limited in Jamnagar (10 mtpa of petcoke gasification capacity) and JSPL in Angul (2 mtpa of coal gasification capacity), but the CO2 is largely released to the atmosphere and not utilized or stored.

Update While there are few pilot scale carbon capture projects (viz. IOCL R&D's amine and biological enzyme-based carbon capture plant and Tata Steel Jamshedpur's pilot scale carbon capture plant for capturing 5 tonnes per day CO2 from Blast Furnace gases), there are no commercial-scale dedicated CCUS projects in India.

While the sustainability of operations and carbon footprint is a major concern for the promoters and top management of most industries, the main impediments to companies investing in CCUS projects are the lack of any policy incentives and framework, lack of a viable or established business model with independent players providing services for the transportation and disposition of CO2 and lack of established pathways & options for the utilization or storage of CO2 at scale.

Given India's climate and CO2 emission reduction commitments, there is a need to design and establish a robust and effective CCUS policy framework to enable projects across the CCUS value chain and at scale for the major industrial sectors of the Indian economy like power, steel, cement, chemicals, and petrochemicals.

Target Clients in India

a)

![]()

b) Large corporations like NTPC, RIL, Adani Group, IOCL, SAIL, Tata Steel, JSW, IFFCO, etc., can be equity investors in carbon capture projects constructed at their plants.

c) Technology and operational investors like Air Liquide, Honeywell UOP, Mitsubishi Heavy Industries Ltd., ION Clean Energy, Baker Hughes, etc., can be equity partners in such projects.

d) Sequestration/EOR site operators like crude oil and natural gas producers (ONGC) can be equity investors in carbon capture and cluster development projects, as they will be utilizing the captured CO2 for EOR.

e) CCUS project financing will also be required as Niti Aayog is planning to set up a Carbon Storage and Finance Corporation of India.

Current CCUS Initiatives/Projects already implemented

NTPC Vidyanchal Super Thermal Power Plant

Carbon Capture Begins at India's Largest Coal Power Plant India's largest coal-fired power plant, NTPC's 4.8-GW Vindhyachal Super Thermal Power Station, has begun capturing carbon dioxide (CO2) from plant flue. www.powermag.com

NTPC has taken the lead and hosted an international seminar also as part of G-20: Read more

Tata Steel - Jamshedpur Steel Plant - 5 MT: Read more

The content of this article is intended to provide a general guide to the subject matter. Specialist advice should be sought about your specific circumstances.