Industrial services providers play a crucial role in enabling their customers (e.g., major utilities, chemical companies, oil and gas companies, and other infrastructure and energy providers) to operate.

To do so, they provide specialized services ranging from maintenance and operations to major construction services. Industrial services providers deploy employees and resources to where their customers need them, which often means workforces are dispersed across a wide geographical footprint. This decentralized approach places decision-making in the hands of field leadership, such as superintendents or general foremen, ensuring operations run smoothly.

In addition to a decentralized workforce, industrial services providers face the added complexity of long-term contracts with their customers. These contracts, often spanning several years, dictate pricing, requiring field leaders to execute efficiently to meet service level requirements while managing costs. In today's inflationary environment, industrial services providers are getting squeezed by increases in labor costs and material costs, which are likely to be exacerbated by tariffs.

Industrial services providers are often unable to raise prices to cover the costs seen in the market, and any increases they can get typically happen on an annual basis, making it challenging to maintain profitability levels without intelligent decision-making to manage costs.

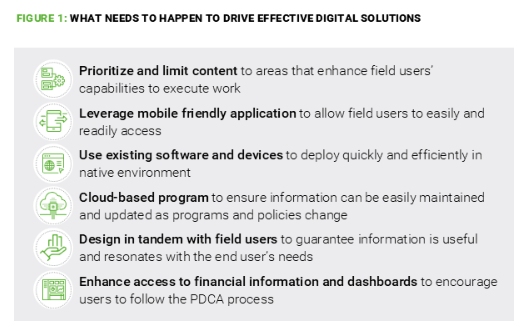

For industrial service providers where decision making is driven at the branch level, it is paramount to get the right information in the hands of the superintendents and general foremen so they can make fast decisions to support job completion. Digital tools are one fast and effective way of getting the right information at their fingertips.

Levers to drive impact to operations teams:

AlixPartners supports Industrial Services companies to design and implement margin improvement programs across key levers. Our work includes optimizing fleets, enhancing field productivity, implementing procurement programs, and enabling the organization through designing an effective operating model.

One powerful enabler for these initiatives is the use of digital solutions to address specific business needs. Rather than building new or purchasing specialized software, existing digital tools can be tailored to business needs or upgraded to achieve key initiatives saving time and cost.

Fleet:

We help clients identify opportunities to standardize equipment needed on projects or drive equipment requests to ensure assets are deployed to revenue. A centralized view of the fleet can enable better decision-making and deployment (or deferral of capital) across the entire business.

Digital tools can help field users learn and follow prescribed processes for fleet and equipment management, reducing maintenance costs caused by non-compliant vendors, weak maintenance practices, and pricing. Additionally, these tools can create access to a "system of record" which will generate and track historical data, supporting future initiatives.

Field Operations:

Another lever we deploy to improve margins is optimizing field operations through effective crew routing, deployment, and performance tracking. Digital tools play a key role in enabling connection to the crew for job routing and scheduling expectations, sharing knowledge management and checklists to apply the Plan / Do / Check / Act routine, and any other day-to-day communications.

Procurement:

We partner with industrial services providers to improve procurement costs by implementing national or regional programs and applying spend controls. When changes happen, like implementing a new supplier or purchasing process, it is critical to cascade information across all relevant teams.

The teams in the field may be the ones making purchases, and getting information to ensure they remain compliant can be a challenge. Digital tools can direct employees to preferred vendors and purchasing systems that drive rebates, maximizing the benefits of agreed rates and prices. In our experience, compliance with programs is key to realizing the full value of cost-saving initiatives.

Industrial services providers can effectively mitigate costs by focusing on key cost levers such as fleet management, field operations, and procurement processes. By prioritizing these cost levers and enhancing their digital capabilities to support improvements in these critical business components, companies can achieve substantial cost savings, maintain strict cost controls, and navigate economic challenges. This proactive and strategic approach helps to ensure long-term financial stability and success.

The content of this article is intended to provide a general guide to the subject matter. Specialist advice should be sought about your specific circumstances.