The Oklahoma Corporation Commission has restricted injection well activity over a combined zone of nearly 10,000 square miles—approximately the size of Massachusetts (Exhibit 1). In Central Oklahoma, the OCC seeks to reduce water injection into the Arbuckle Formation by at least 300,000 bpd. Furthermore, the OCC now requires new injection well applications to go through a full-court process, and approval can be granted only by a majority vote of commissioners. Furthermore, any permit approved is limited to six months, and contains requirements for seismicity monitoring and regular testing, and, perhaps most important, existing wells in the Area of Interest can be shut-in with no prior court hearing.

Exhibit 1: Areas Affected by the OCC Injection Well Orders

Source: Oklahoma Corporation Commission

These reductions will pose immense operational challenges for producers. Roughly half of Oklahoma's more than 6 million barrels per day of produced water are injected down saltwater disposal wells. The other forty seven percent of the state's produced water is re-injected into producing formations to enhance oil recovery.

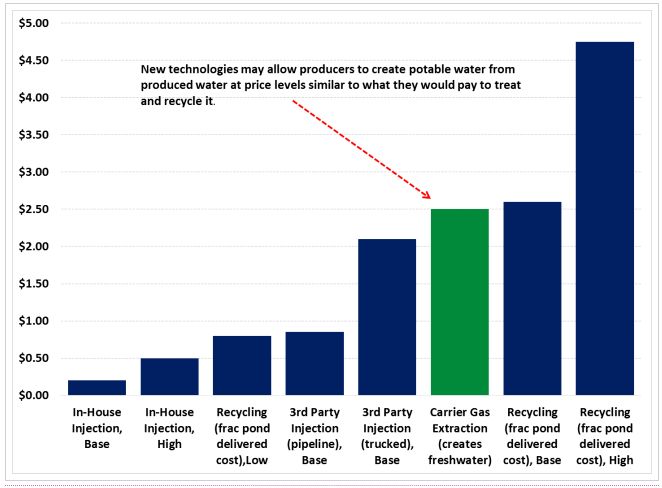

The injection curtailments create significant economic risks for producers already struggling with low oil prices. Underground injection is by far the most cost-effective method of produced water disposal. For instance, injecting the water into deep formations such as the Arbuckle likely costs approximately $0.20 to $2.00 per barrel depending on whether it is trucked or piped, whereas purifying and reusing or re-purposing the water can cost substantially more (Exhibit 2).

Nonetheless, emerging recycling technologies are lowering the cost threshold of treating produced water to drinkable purity—potentially to levels matching or surpassing the economics of treating and recycling it for oilfield use. For one of the most promising—carrier gas extraction (CGE)—the MIT engineers who have helped develop the technology say water can be treated for as little as "a couple dollars a barrel." Academic research supports this assertion, showing that the costs of carrier gas-extraction water purification have dropped significantly, falling from nearly $5/bbl to an estimate of less than $1/bbl for a newer small-scale test system. It is likely that as CGE providers gain experience working with produced water and make further technical improvements, the industrial-scale cost of turning produced water into potable freshwater will fall toward $2/barrel or less and be competitive with existing disposal options in many cases.

Exhibit 2: Estimated Oilfield Water Disposal and Recycling Costs, $/bbl

Source: Company Reports, Author's Analysis

For full-fledged recycling, promising technologies exist, but scaling up quickly will be a challenge. For instance, carrier gas extraction—in essence the natural rain cycle bottled up in a tower—is one of the lower cost technologies capable of purifying salty and oily produced water to drinkable specifications. Yet to date, the facilities run by Gradient in the Permian Basin can handle only 12,000 bpd of produced water. Oklahoma producers will need access to potentially nearly 30 times this volume of recycling/processing capacity to handle the OCC restrictions as they stand today.

Several recycling/purification service providers note that their systems are designed to be modular. As such, one possible solution would be to integrate a scalable modular treatment facility with existing produced water handling infrastructure in the zones affected by the OCC decree. One major operator owns a produced water gathering system in the Mississippian Lime area capable of handling 3 million bpd of produced water. Another operates a produced water gathering loop in Woods and Alfalfa counties that it claims can handle 345,000 bpd of fluid. Both operators have expressed interest in selling capacity on their systems to third parties.

These systems lie within the OCC restricted zone and potentially could serve as natural aggregation points with which water treatment systems could be integrated. In many cases, it would not be necessary to treat the entire system capacity of produced water, but rather just those barrels that have been displaced by shutdowns and deratings of key injection wells. This setup would initially pose steep technical challenges, but the emerging Oklahoma oilfield water crisis might just be the forcing function needed to hasten industrial-scale recycling and repurposing (i.e., treatment to a potable freshwater standard) of produced water. As technical innovation advances, key legal barriers remain, particularly the inability to store produced water from multiple operators in a single pit or tank facility.

Options and Potential Legal Issues

- Recycling and Reuse of Produced Water (Single Operator)

The Oklahoma Administrative Code contemplates the use of noncommercial pits capable of holding more than 50,000 barrels of flowback fluid, i.e., produced water (Okla. Admin. Code 165:10-7-16). Constructing and operating such pits subject an operator to multiple pages of regulatory requirements. Key standards include no construction of pits within a 100-year flood zone, a minimum of three monitor wells must be installed (one upgradient and two downgradient from the pit), the pit must have at least three feet of freeboard, and such produced water pits shall have a geomembrane liner at least 30 mil thick. Id.

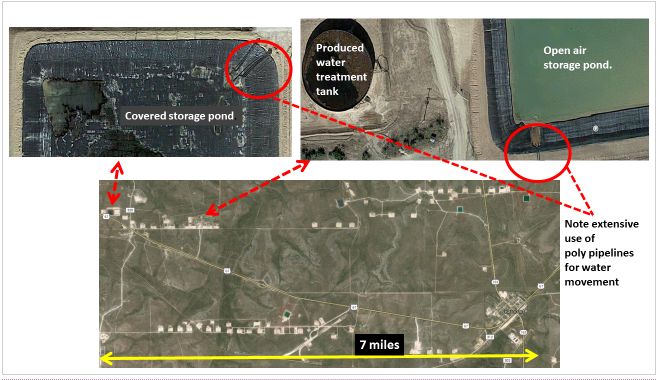

Producers that opt for pit-based storage and recycling can draw upon the experience of operators in the Texas Permian Basin. These companies have used lined pits linked by poly lines to create water supply systems that allow them to recycle up to 100 percent of their produced water and augment it as needed with brackish groundwater unsuitable for farming or domestic use, which frees them from dependence on local freshwater supplies. Exhibit 3 (below) shows integrated produced water handling and recycling systems in Irion County, Texas. Operators are using these systems to support fracs that consume as much as 200,000 bbl of water apiece. While the Permian Basin operators are also integrating local brackish groundwater into their supply system, the sheer volumes of available produced water in Oklahoma mean that similar infrastructure there would likely use only produced water.

Exhibit 3: Irion County Texas Field-Scale Produced Water Recycling/Brackish Water System

Source: Google Earth, Author's Analysis

- Recycling (Co-Mingled Water From Multiple Operators)

Current Oklahoma law precludes the most economically efficient options for water recycling because the pit operator and produced water generator must be the same entity. A "noncommercial pit" is defined as "an earthen pit which is located either on-site or off-site and is used for the handling, storage, or disposal of deleterious substances or soils contaminated by deleterious substances produced, obtained, or used in connection with the drilling and/or operation of a well or wells, and is operated by the generator of the waste." Okla. Admin. Code 165:10-1-2. Disallowing co-mingling of produced water from multiple operators prevents them from sharing infrastructure in one of the most important segments of the water chain—treatment and storage.

To address this critical shortfall, the Oklahoma Legislature should consider language along the lines of that adopted by the Texas Railroad Commission, which allows a party to accept produced water from multiple producers, co-mingle it, and treat it:

(41) Non-commercial fluid recycling—The recycling of fluid produced from an oil or gas well, including produced formation fluid, workover fluid, and completion fluid, including fluids produced from the hydraulic fracturing process on an existing commission-designated lease or drilling unit associated with a commission-issued drilling permit or upon land leased or owned by the operator for the purposes of operation of a non-commercial disposal well operated pursuant to a permit issued under § 3.9 of this title (relating to Disposal Wells) or a non-commercial injection well operated pursuant to a permit issued under § 3.46 of this title (relating to Fluid Injection into Productive Reservoirs), where the operator of the lease, or drilling unit, or non-commercial disposal or injection well treats or contracts with a person for the treatment of the fluid, and may accept such fluid from other leases and or operators. 16 Tex. Admin. Code § 3.8

- Full Treatment and Surface Discharge/Sale of Treated Water

As carrier gas extraction and other purification technologies mature, operators may also increasingly find it more economical to treat water to a potable standard and discharge or sell it, rather than truck or pipeline it to distant disposal facilities outside the OCC area of interest. For operators that can bring Total Dissolved Solids (TDS) or Total Soluble Salts (TSS) below 5,000 mg/l and oil and grease below 1,000 mg/l, the OCC will likely issue them a permit for direct surface discharge of the water. Okla. Admin. Code 165:10-7-17. Surface discharge also requires that the land have an Exchangeable Sodium Percentage no greater than 15, a maximum slope of 5 percent, at least 20 inches' depth to bedrock, and slight salinity in the topmost six inches of the soil (electrical conductivity of less than 4,000 microohms/cm). Id.

Realistically, water treated with carrier gas extraction would be much more pure—essentially the quality of distilled water—and so operators would likely be able to seek surface discharge and/or the ability to discharge directly into waterways. This would entail additional permitting work under the Federal Clean Water Act and other relevant state and local laws, but it raises interesting possibilities.

Finally, water capable of meeting the standards enumerated above might also be a candidate for sale to agricultural or other interests in need of freshwater. There is a precedent for such actions. As of April 2015, farmers in California's parched, but fertile San Joaquin Valley had used at least 25,000 acre-feet (8.15 billion gallons) of treated produced water to irrigate crops. If industry can provide treated produced water to farmers under California's tough regulatory regime, it stands to reason that under Oklahoma's more pro-market political system, such transfers would be highly feasible assuming water can be treated to a truly potable standard.

The Salt Challenge

Distillation of salty oilfield water leaves behind a superconcentrated brine. Converting this into dry salt likely will not be the solution, for the salt volumes are simply too large. If 1 million barrels per day of produced water from the Mississippian Lime with a TDS concentration of 190,000 mg/l that was 80 percent sodium chloride were completely distilled, 8.8 million tonnes per year of salt would be left behind—more than 20 percent of annual U.S. salt production.

This massive rock salt volume would crater salt prices and also pose severe logistical challenges—imagine mile-long unit trains of salt crossing the prairie. A more practical solution is to distill the water until a fluid-concentrated brine is left behind, and then inject this waste stream into deep disposal wells. Such an outcome would help industry repurpose valuable water, minimize the salt mass balance problem, and dramatically reduce the volume of fluid injected into the Arbuckle and other formations that may be vulnerable to seismic activity.

Conclusion

The OCC's produced water injection restrictions pose a serious operational and economic challenge to Oklahoma oil and gas operators. Technological solutions providers will seize this opportunity to test oilfield water treatment options in an environment of necessity, and at an unprecedented scale. A tougher challenge will be crafting the appropriate legal and regulatory frameworks to maximize the positive impacts of technology and allow Oklahoma's dynamic and entrepreneurial oil and gas operators to continue developing the state's resources and creating economic opportunities for the state's citizens. The OCC should kick-start this process by looking to the Texas Railroad Commission and its forward-looking fluid recycling rules.

The content of this article is intended to provide a general guide to the subject matter. Specialist advice should be sought about your specific circumstances.